Meet the Master Crafters: Part VI

Dariusz Barczak - Senior Fabricator

Dariusz and his wife Beata both work here at Northern Lights. Originally from Poland, they came to the UK over ten years ago. We chatted with Dariusz to find out more about his role as a senior fabricator.

Tell us a bit about your background. When did you move from Poland to the UK?

I moved from Poland to the UK in 2005. When I first came here, I said I'd only stay here for three months – but I've now been here over 16 years, 15 years of those I have worked for Northern Lights.

At first, my wife came to England with our son every summertime for two months, and I would go back to Poland for Easter and Christmas. But I didn't get to see my son growing up. So she said to me if you find a house and a school, we'll stay in England. The following week I did that, and now we have been here for a long time!

Was the language barrier a challenge at first?

My English isn't perfect, but Oskar - my son - speaks English perfectly after three months. He enjoys it, and if he is happy, we are happy; that's what's important. Beata wanted to learn English and speak to people, so she went to college. She speaks better than me – just not as much!

I asked, 'how do you understand a drawing if you don't speak English?' But the job is no different in my country so even though my English wasn't excellent at the start I was good at my job. And if I don't understand something, I'll ask once and then twice. I want to know something; I'll never guess anything.

Did you train in welding in Poland?

I finished college in welding and fabrication in Poland, so I had all my qualifications before coming here. I think I'm suitable for this job.

I've worked in Germany and Poland, even once I was working making Christmas decorations from glass (glass blowing) and welding and fabrication. In my first job in England, I welded big lorries and welding big wagons. But I didn't enjoy it as much as it was the same thing every day. I like progress and being interested and challenged.

Is that what appealed to you about working at Northern Lights?

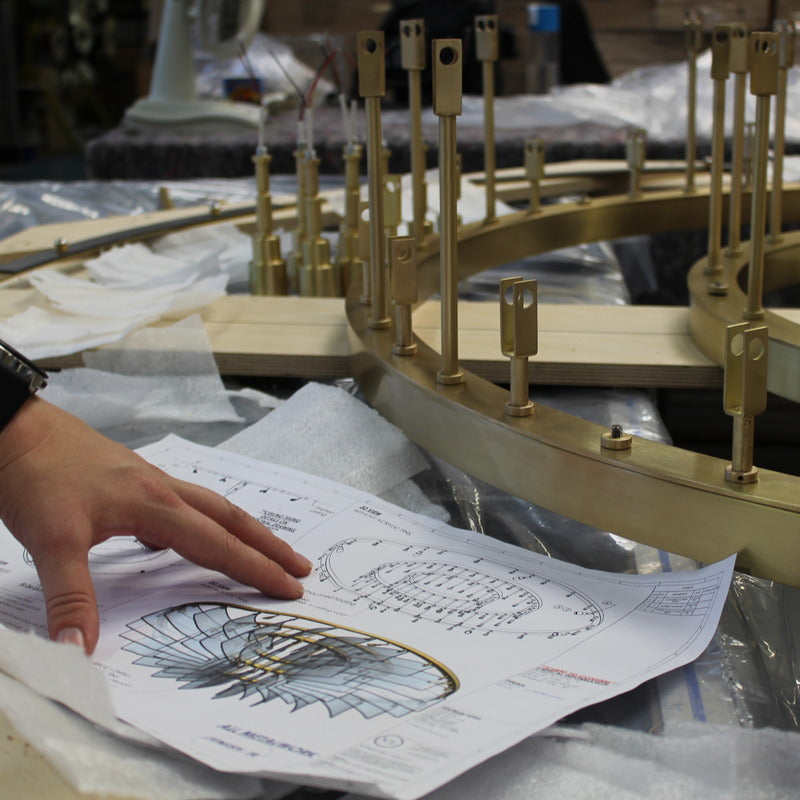

Yes. No two days are the same. I'm one of the first to make a great fitting from stainless steel. It was about five metres in diameter when they mainly did smaller wall lights and lamps. We also needed to put a glass inside it; it was a big job, and I welded it all together. Then from there, it was a lot bigger and different jobs; I don't particularly appreciate doing the same thing all the time. Life is too short.

MIG vs TIG welding: what's the difference?

MIG welding is heavy duty, so we'd use this for the heavy pieces. TIG is more intricate work. How many welds, how strong the weld needs to be, how to apply the weld, thickness, and the type of materials are all things that will tell you which weld you need to use. TIG is cleaner, and there is a lot of skill involved; I like working with TIG.

Do you enjoy design?

I'm passionate about design at work and at home. But my wife thinks about the design part more, and I make things for her. I like making things that no one else has – unique. So it's different. We have a big kitchen, so I made a table and know no one else will have the same.

How have things changed since you first started?

We have a lot more younger people here now. We used to do a lot more traditional lighting. But now, the design is different, the quality has become even more critical, and nothing but the best is accepted. We do more complicated stuff now on the large installations. We had a 500 kilogram light to make for a job in Dubai, and for this, you need to put a different weld – half a tonne is pretty heavy and a different challenge to ensure it's solid and secure.

Why do you think there are fewer women in welding?

I don't know why. I think it doesn't matter if you're male or female. The world is changing now; more women are driving lorries and buses and doing jobs only men previously have done. Women can do the same technical, complicated welding challenges as men; the only time it's more difficult is if there is a heavy item. I have respect for women and know they are capable of doing anything that any man can do.

What do you do in your spare time?

I weld seven days a week, even at home in my workshop. I love to make parts for classic cars and classic bikes outside of work, where the parts no longer exist, and you can't buy them anywhere – so they need to be made. I've done it before, and I enjoy that. I love it.